Get PRO Pricing

Get [PRO] Pricing

Similar to all other industries, the plumbing industry has undergone vast technological developments, specifically within the internal construction of faucets. Within the common faucet, cartridges are generally used to control the water flow.

Originally, faucets operated on a compression cartridge. A rubber washer would be compressed by a shaft in a corkscrew fashion against a circular bushing, known as a seat, until enough pressure was made to create a seal. When the faucet was turned on, the shaft inside raised and released the pressure from the seal, which allowed water flow. Unfortunately, the drawback to this mechanism is that both the washer and seat would deteriorate over time, allowing dripping. Both the seat and washer had to be replaced quite frequently.

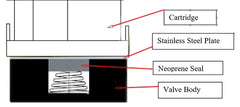

Then, a little over 60 years ago, innovator Al Moen fabricated the modern washerless cartridge. Instead of the wear and tear of the compression cartridge, the washerless cartridge consists of a neoprene donut-shaped stopper that which seals the flow of water by maintaining constant pressure against a steel plate with the aid of a spring. The plate has a crescent-shape opening, so as the cartridge turns, the opening is aligned with the opening of the neoprene seal, allowing water flow. As the faucet is turned off, the opening of the seal is blocked by the solid portion of the stainless steel plate, blocking water flow.

Despite its superior durability compared to the compression cartridge, the washerless cartridge’s neoprene seal may eventually break down and the spring may weaken, potentially allowing leakage. However, both parts are very inexpensive and readily available, making for an easy repair.

The most modern development has emerged from Germany. The ceramic carbide cartridge was constructed to be the most lasting cartridge to date because ceramic carbide is impervious to friction and can withstand frequent use. Additionally, there was purposefully no usage of springs, washers, or any rubber components to further reduce mishap and maintenance. This system consists of a self-contained cartridge that holds two ceramic carbide discs with two opposing triangular cut-outs on each of them. When the faucet is turned on, the top and bottom openings are aligned, allowing water flow. As the valve is turned off, the openings are now no longer aligned and are blocked by the solid portion of the cartridge, halting water flow.

Unfortunately, nothing is perfect and this system has one minor flaw. Ceramic carbide is brittle and only becomes an issue if debris enters the line and gets lodged into one of the openings. It blocks the proper closing of the valve and water flow may not be stopped. If the user applies extra pressure, the disc may crack, making the faucet inoperable. Luckily, replacement is simple. However, if the cartridge is not covered by warranty, the mend may become somewhat expensive.

There are several aspects to consider when making any big purchases. Considering the costliness of renovations or new homes, homeowners should not overlook the intricacies and technicalities of appliances. Fortunately, Kingston Brass is a top-of-the-line kitchen and bath source with state-of-the-art products to help you in all of your interior design decisions.